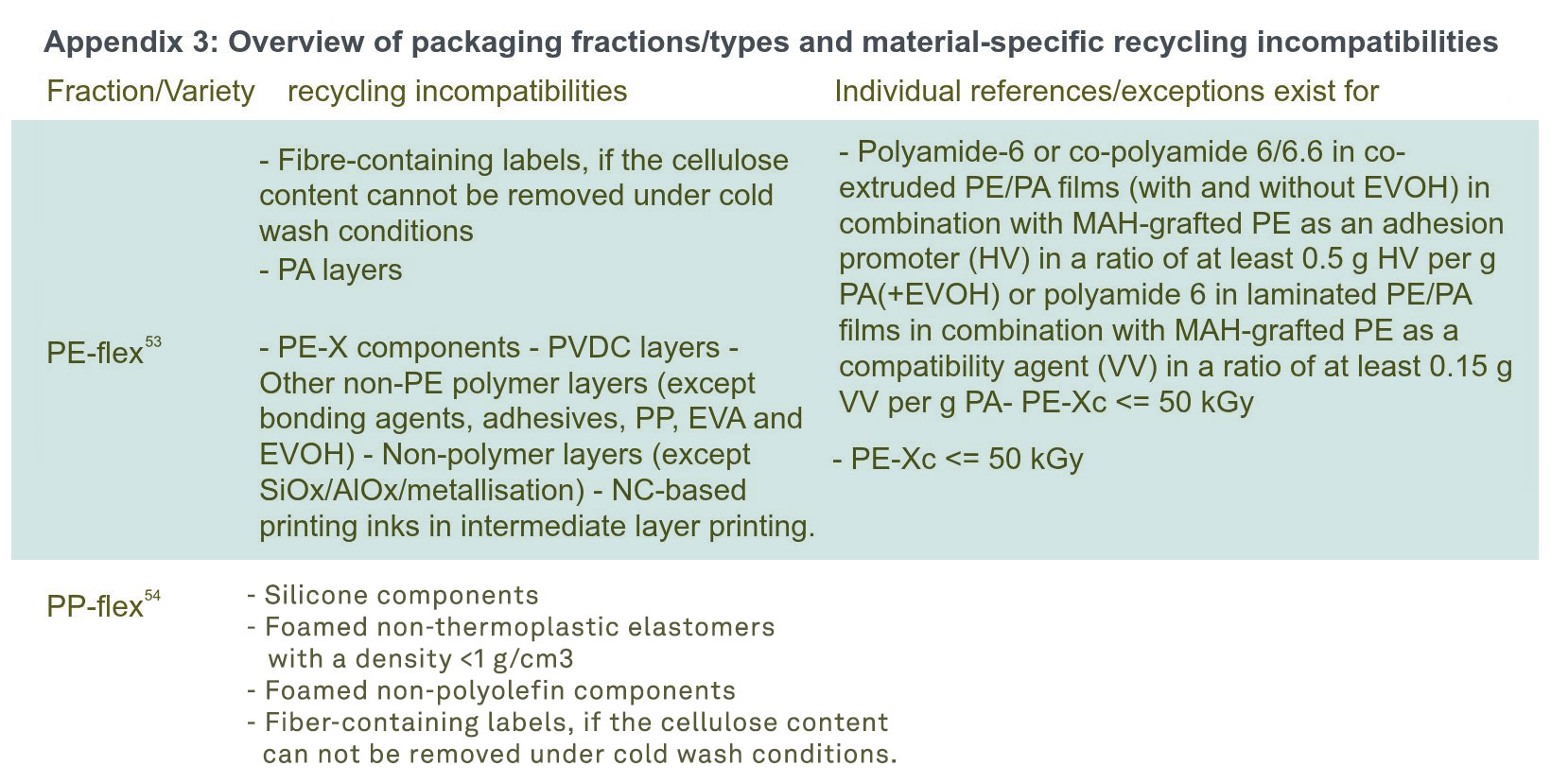

Assessment of polyolefin composites

Another step in preparing for the PPWR in the minimum standard was the introduction of so-called reference applications in 2024. These involve the allocation of sorting fractions and production processes in which the respective recyclates must be processable in future.

For the sorting fraction of PE films (PE-flex), these are blow film extrusion and injection moulding

for the sorting fraction PP films (PP-flex), these are injection moulding and thermoforming

Due to the high demand for homogeneous granulate quality in blown film extrusion, PP content in PE-flex is completely deducted when assessing recyclability. PE content in PP, on the other hand, is fully credited as a recyclable material.